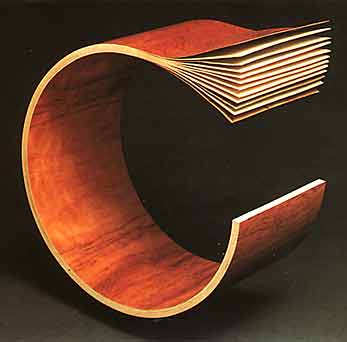

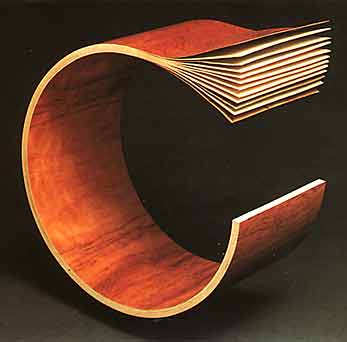

1987

|

|

|

|

|

|

|

FEATURES:

Sonor Wood Shells

Basis for a better sound

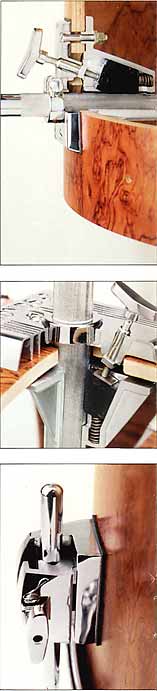

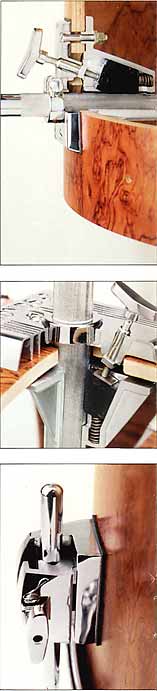

Beech and birch, being two of the world's strongest timbers, are the basic materials for all Sonor drum shells. Both woods have a uniform density, so that their surfaces are smooth, firm and resistant to wear. Because of their outstanding acoustic properties and their flexibility and resilience, they are ideally suited for the production of drum shells.

Construction of the wood shells

The highly solid Sonor shell is produced by a special forming procedure. This process includes the cross laminating of the separate plies. There are also no sound restraining reinforcement hoops or shell supports, so the shell has a minimum of vibration and the same level of stability at every point.

"floating heads"

In order to allow a drum head vibration unaffected by secondary

|

|

|

|

noise, we use the principle of floating heads, which is also used for concert tympani. The sizes of the Sonor shells and rims prevent a contact of the drum head rim to the shell. Measurements show that

|

|

|

|

vibrations are projected in the best possible way when there is an angle of 45° from the edge of the shell to the head. Accordingly, the top and bottom edges of Sonor shells are beveled at 45°.

|

|

|

|

|

|

|

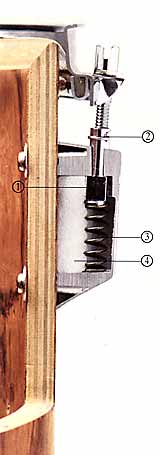

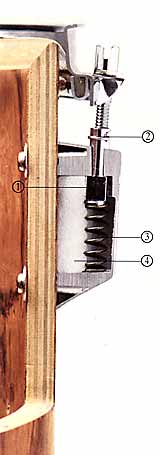

A clamping ring above the thread housing is pressed against the tension screw, which is flattened on two sides. When the screw is tightened it will lock at every half turn, securing its position. The tension screws of the snap lock can be easily turned with a Sonor drum key, in contrast to the lock and nut system which is a difficult and more time consuming process. For best results in head changing we recommend spin keys Z5071 and Z5072.

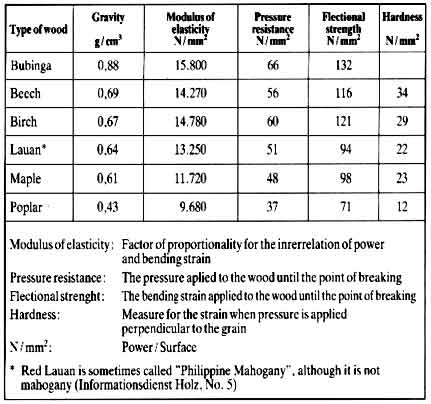

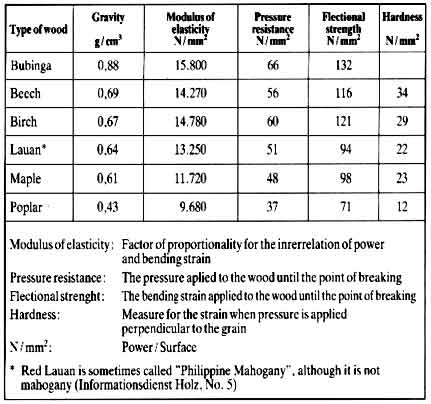

Shell mounts

The shell mounts on tom toms and bass drums are holders in two respects. First, on all Sonor shell mounts the tom holders are fixed by tightening a wing screw down on a spring loaded and steel reinforced nylon wedge, and is double secured by means of a fix clamp.

Second, the mount is held securely on the drum by 2-point drilling of the toms and 4 point drilling of the bass drum. The mount has a full outside and inside allowing tremendous weight to be mounted on bass drums without the mount loosening.

Bass drum spurs and floor tom legs (DGM)

Bass drum spurs and floor tom legs are adjusted by prism clamps, which enclose a section of the spur or leg making slippage virtually impossible. The prism clamp itself is fixed to the shell at 3 points. The spurs are of a superior non-creep design, and are quickly adjustable from rubber feet to metal spikes to keep the bass drum rigid on any surface. The floor tom legs are equipped with solid rubber feet.

|

|

|

|

FEATURES

|

|

|

|

Manufacture of metal drum shells

Sonor metal shells are made of seamless ferro-manganese steel. Like the wood shells, these shells are designed to have minimal vibration of their own, allowing an optimal vibration of the head. A flat steel disc is formed into a perfectly round shape on a projection machine. Cold forming ensures a regular wall thickness and a high stability of the shell. In the following galvanization process, every shell is first copper plated, then nickel plated and finally chrome plated.

Fittings

The drums, rims, lugs and tension screws are parts that take the most stress. Therefore, special care is devoted to their production. Similar to the snare drum shells, the rims are formed seamless from ferro-manganese steel. The flanged rim with its beaded upper edge allows clean rimshots and prevents a high breakage of sticks.

Sonor tension screws for snare drums, tom toms and floor toms have the characteristic slotted cylinder head and can even be turned with a coin id there is no key at hand.

The inside of the drum lugs consists of:

1. Thread housing made from nonferrous metal, to prevent high wear.

2. "Snap-lock" fixing the thread to prevent the head from going out of tune.

3. Tension spring as a bedding for the thread-housing

4. Foam lug insert to prevent rattling.

Snap Lock (patented)

The "Snap Lock" system, developed and patented by Sonor, is an important innovation in drum making. It prevents the tension screws from loosening and causing the drum head to come out of tune during play. The system is as simple as it is effective.

|

|

|

|

|

|

The high level of stability of all Sonor drum shells is ensured by cross-laminating several plies of wood.

Illustrated below is a 12-ply Signature shell.

|

|

|

|

|

|

|

Cutaway of a Sonor lug

|

|

|

|

|

|

Cutaway of tom tom mounts (top) and bass drum mounts (center)

Prism clamp for floor tom legs (bottom)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|