|

THE F0RCE F0R THE 90s

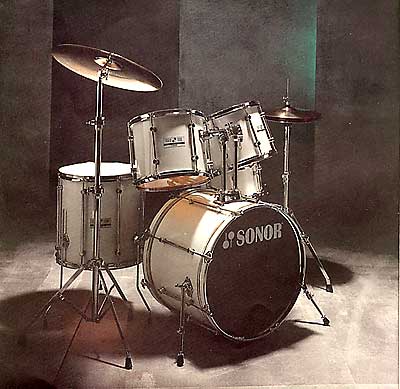

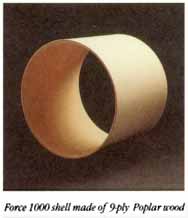

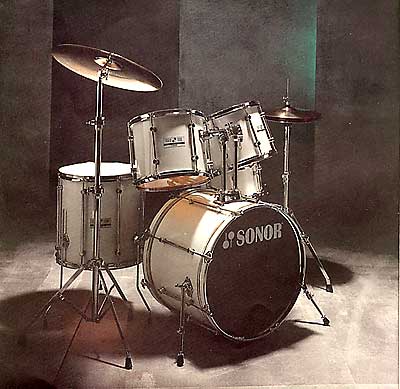

From Sonor, the world's leading manufacturer of high quality percussion comes another big drum innovation. Introducing the Force 1000 Series. Force 1000 drums are made in Germany to the same exacting manufacturing standards as the popular Force 2000 series. They offer a sound quality that Sonor drums are famous for at a price that now anyone can afford. Force 1000 drums feature the same tubular lug design as the Force 2000, 3000, and Hilite Series. Its 9-ply poplar wood shells are the foundation for a great drum sound with high projection. A choice of three color finishes is available: High gloss black, white, and red. The Force 1000 snare drum has a 9-ply poplar wood shell for a warm and brilliant tone. it is supplied with a solidly built strainer for smooth and effective snare action. A complete new hardware range comes with the Force 1000 series including chain drive bass drum pedal and hi hat stand, cymbal and cymbal boom stands, snare drum stand, double tom holder and stand. The rugged chains on hi hat stand and bass drum pedal ensure fast and reliable action. Specially designed foot plates give comfortable playing feel and anti-slip security. The snare drum stand is supplied with large sized rubber arms for solid grip on the drum and a handy tension nut for easy adjustment. All stands come with memory clamps for quick and easy set tip. Force 1000 is the best choice for any discerning drummer looking for Sonor quality at a budget price.

|

|

|

|

|

|

|

|

|

|

|

QUALITY DRUMS MADE IN GERMANY

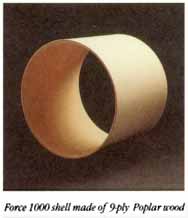

Force 1000 drums are made in Sonor's factory in Aue/Germany. 9 plies of poplar wood are hand selected for each drum shell. They are then cross laminated in Sonor's heat forming presses for maximum strength and perfect roundness. All bearing edges are bevelled to 45° angles for minimal head to shell contact and uninhibited drum head vibration. The celluloid covering is affixed with Sonor's own special process to ensure complete surface adhesion. Computer controlled machinery is used for precision drilling of the shells. Finally all Force 1000 drums are assembled by hand and go through a series of quality controls before being packed and shipped to drummers around the world.

|

|

|

|

|

|

|

Selection of poplar wood used for 9-ply Force 1000 shells.

|

|

Cross lamination of the shells in Sonor's own heat process.

|

|

Unique Sonor celluloid covering process.

|

|

|

|

|

|

|

|

Computer controlled machinery guarantees precision drilling.

|

|

Hand assembly of all drums with strict quality control.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|